70% of the components we produce are through-hole parts for the automotive industry, with the remaining 30% consisting of specialized stepped rivets and other custom parts.

Our facility is equipped with around 20 machines for cutting and secondary processes. Cold-headed parts are machined in-house through cutting and secondary processing operations before shipment.

We manufacture through-hole components with diameters ranging from φ5 to φ13, and lengths ranging from approximately 8 mm to a maximum of 35 mm.

Currently, over half of our production is focused on diameters between φ6 and φ10.

Product Samples

Resin Insert Component with Thread (Nickel–Zinc Alloy Plating)

Both-End Swaged Component (Annealed)

Both-End Swaging (Annealed)

Single-End Swaging (Annealed)

L33 mm Through Component (Steel)

Shaft Outer Diameter Grinding ±0.003 mm

Single-End Swaged Component

1.1 mm Wall Thickness Through Component + Outer Diameter Grinding

Why Choose Adachi

Round-the-Clock Production for Regular and Rush Orders

Our cold forging with parts formers operates on a 24-hour production system.

We can accommodate urgent requests and small-lot orders, offering flexible proposals tailored to a wide range of needs.

Cost-Effective, Versatile Secondary Processing

With our extensive in-house equipment, we handle various secondary processes such as grooving, chamfering, tapping, and polishing.

By running unmanned production at night, we reduce costs while ensuring the manufacturing of high-quality products at competitive prices.

Rigorous Quality Control System

Our factory is ISO 9001 and ISO 14001 certified.

To meet the strict quality requirements of automotive components and other industries, every product undergoes thorough inspection using advanced testing equipment before shipment.

Flow from Inquiry to Delivery

- 1. Inquiry

- Please contact us via our [Inquiry Form] or by phone at [+81-48-766-2338].

We will confirm the details of your request and arrange a meeting schedule.

- 2. Meeting & Quotation

- We will discuss the purpose and specifications of the required parts and provide an estimate for the lead time and cost.

If possible, please prepare a sample of a similar part or a specification sheet in advance.

- 3. Production & Processing

- We can manufacture a wide variety of parts using cold heading with our parts former, followed by secondary processes such as cutting, drilling, and tapping.

- 4. Inspection

- After production is completed, all parts undergo thorough inspection in our in-house quality control room.

- 5. Delivery

- Products that have passed inspection are packaged and delivered to your designated factory or location.

Product Lineup

【Processing Categories】

・Header Forming

・Thread Rolling

・3D Modeling

・Forging Die & Header Die Design

・Surface Grinding

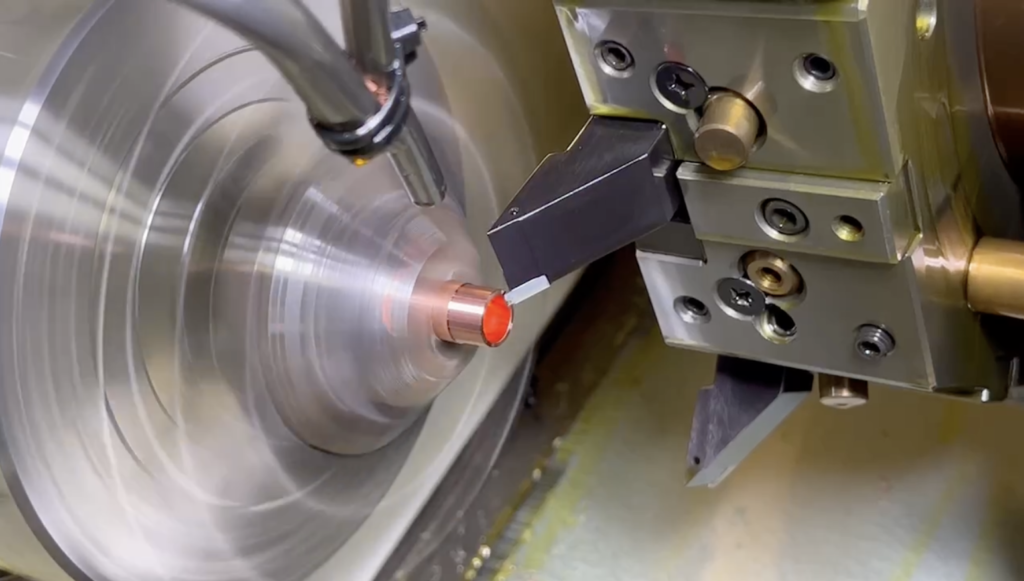

・Cylindrical Grinding

・Centerless Grinding

・Automatic Lathe Machining

・Bench Lathe Machining

【Materials Processed】

・Iron

・All types of stainless steel

・Aluminum

・Brass

・Copper

※We also accommodate difficult-to-machine materials.

Contact

We welcome inquiries about parts manufacturing,

quotations, or any questions regarding our services.

Please note that we do not accept sales or promotional inquiries.

We are also available via email or phone.