Manufacturing Technologies

Cold Forging with Parts Formers

Our cold forging process is performed at room temperature, ensuring minimal distortion and exceptional dimensional accuracy.

With a monthly capacity of approx. 5 million units and 24-hour operation,

we respond swiftly to urgent orders and offer flexible support for small-lot production.

Solution Examples

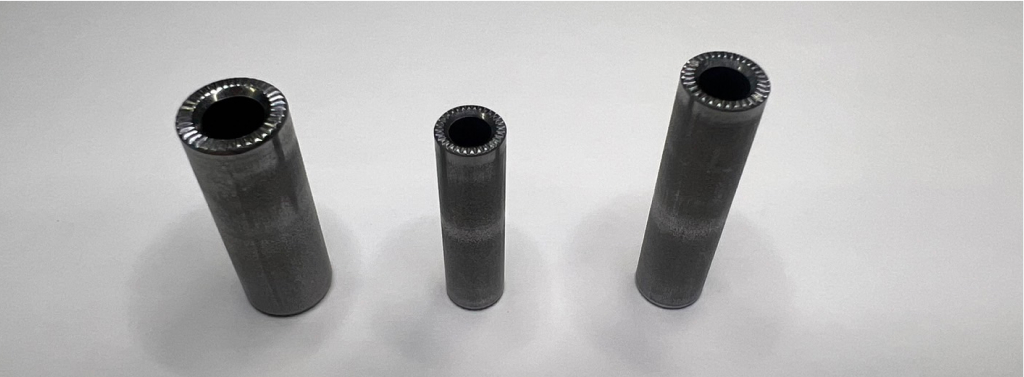

Improved Productivity and Reduced Costs through Cold Heading Conversion from Machined Components

Compared to machining, cold heading generates significantly less material waste, resulting in high production efficiency and reduced costs.

Enhanced Productivity through Cold Heading of Elliptical Shapes

Elliptical components require special forming techniques, as uniform force cannot be applied during shaping. Leveraging our many years of expertise, we are capable of manufacturing high-precision elliptical components with exceptional accuracy.

Quality Control

Our factory is certified under ISO 9001 and ISO 14001.

We have obtained ISO 9001, the quality management standard certified by the International Organization for Standardization (ISO), and manufacture our products under a rigorous quality control system.

In addition, we have acquired ISO 14001, the environmental management system standard, and are committed to conducting business activities with due consideration for the environment.

Equipment Overview

Manufacturing Process

After cold heading with a parts former, our products undergo secondary processing—such as cutting, drilling, and tapping—using two-spindle secondary processing machines, followed by heat treatment, rigorous product inspection, before packaging and shipment.

Contact

We welcome inquiries about parts manufacturing,

quotations, or any questions regarding our services.

Please note that we do not accept sales or promotional inquiries.

We are also available via email or phone.